FOAM FILLED OIL & GAS BUOYANCIES

Made from a core of Polyethylene foam, OCEAN 3’s range of Foam Filled Buoys & Floats are able to absorb high impacts without incurring damage to their resilient body, or to the hull of the Vessel handling or hitting them. Our range of Foam Filled Buoys have numerous advantages over conventional steel Buoy construction.

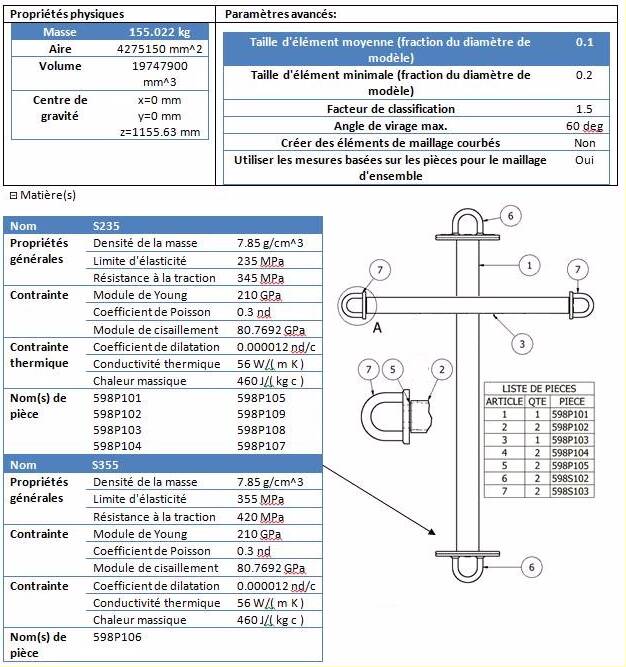

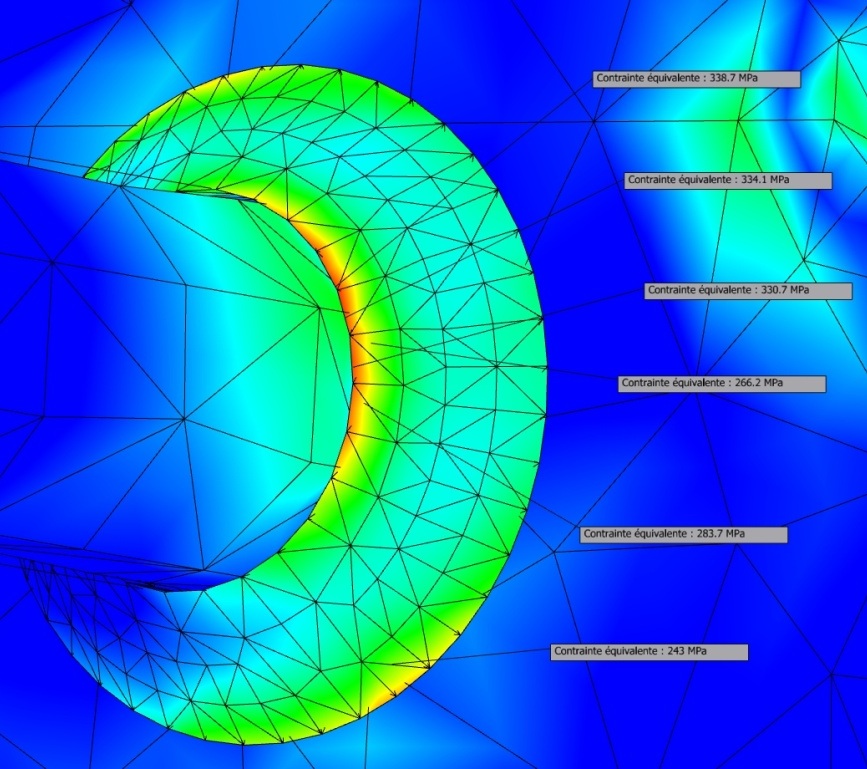

The manufacturing processes and raw materials used to build OCEAN 3’s Buoys & Floats are very similar to those applied to our Foam Filled Mobile Fenders : a resilient 100 % closed cell Polyethylene foam, including a steel frame, made to take the forces generated by the riser chain in view to protect the outer "soft" body, which is encapsulated in a tough reinforced Polyurethane coating.

I - TYPOLOGY OF FOAM FILLED BUOYS AND FLOATS

A) FOAM FILLED UTILITY FLOATS

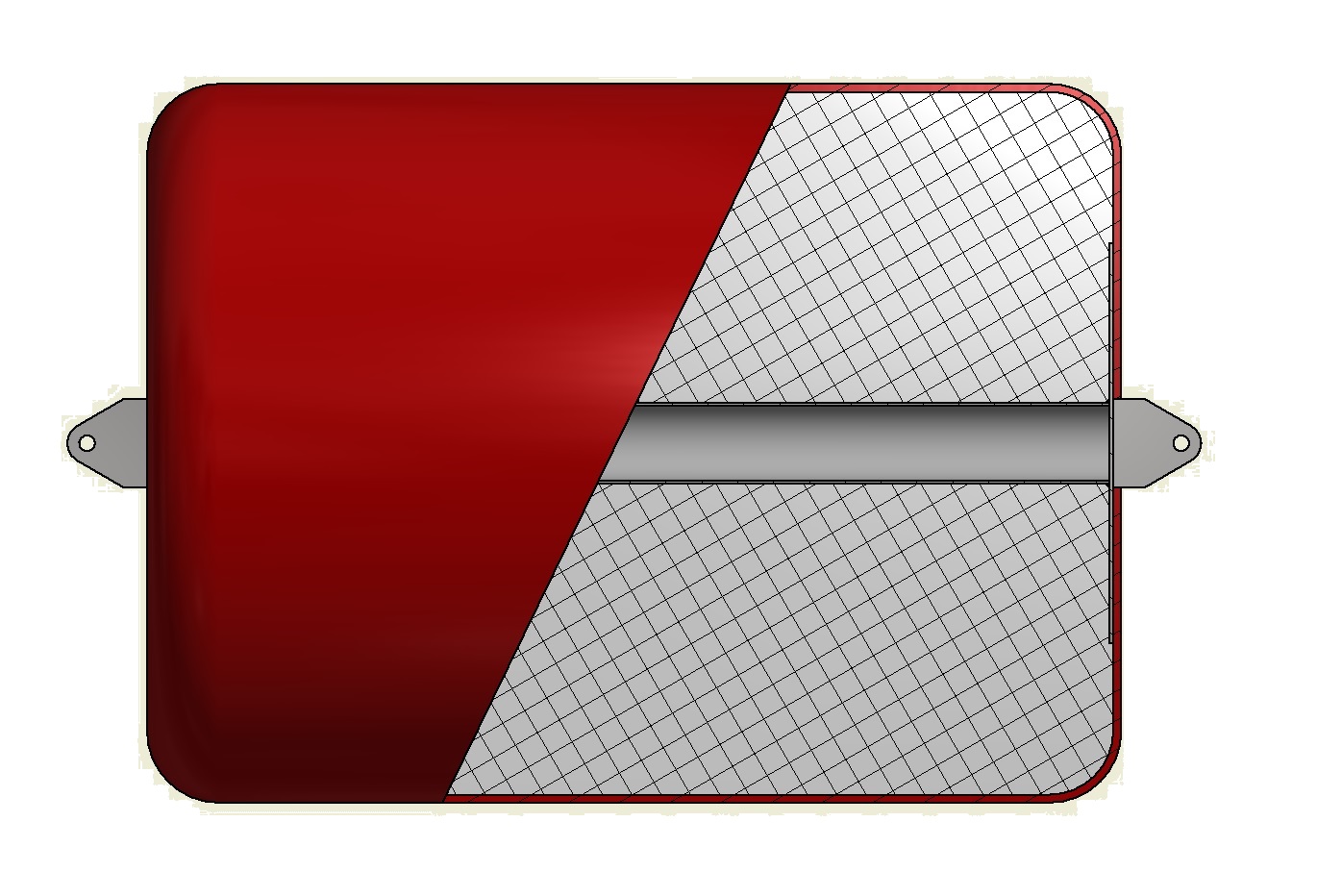

Most common buoyancies are from 0,5 Tons to 2,5 Tonnes (or more) - Cylindrical or rectangular in shape – Steel frames fitted on each end with a mooring pad eye.

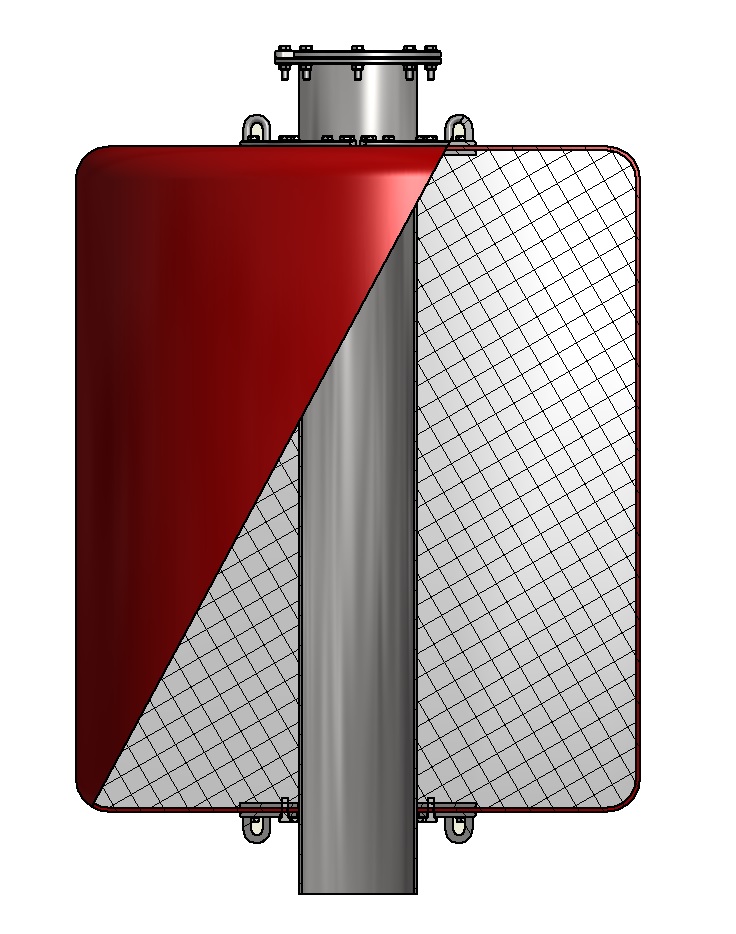

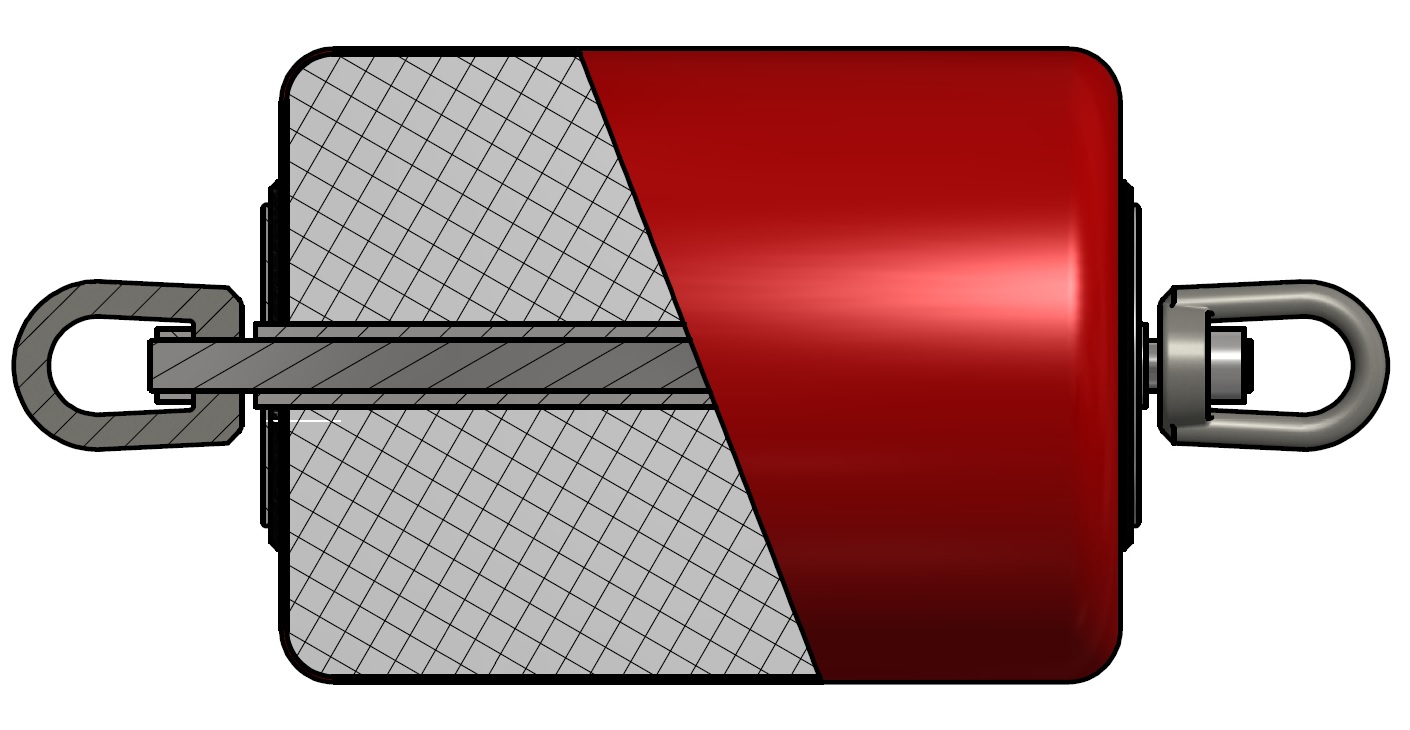

B) FOAM FILLED CHAIN SUPPORT BUOYS

Ocean 3 Foam Filled Chain Support Buoys ranging from 2,5 Tons to 10 Tons (or more) - Cylindrical or rectangular in shape - Fitted on each end with mooring pad Eye or Swivel or mixed depending on use.

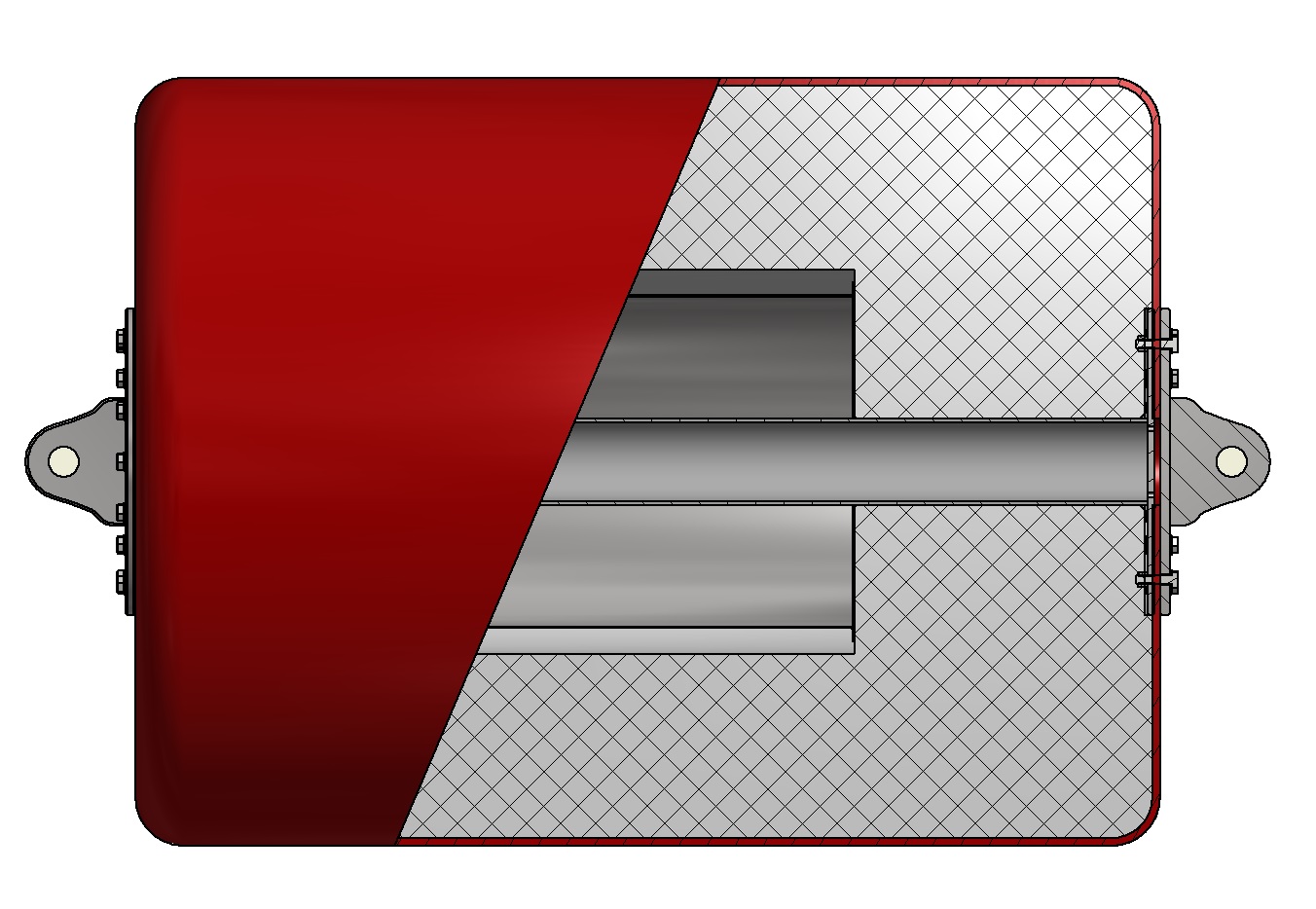

C) FOAM FILLED CHAIN TROUGH SUPPORT BUOYS

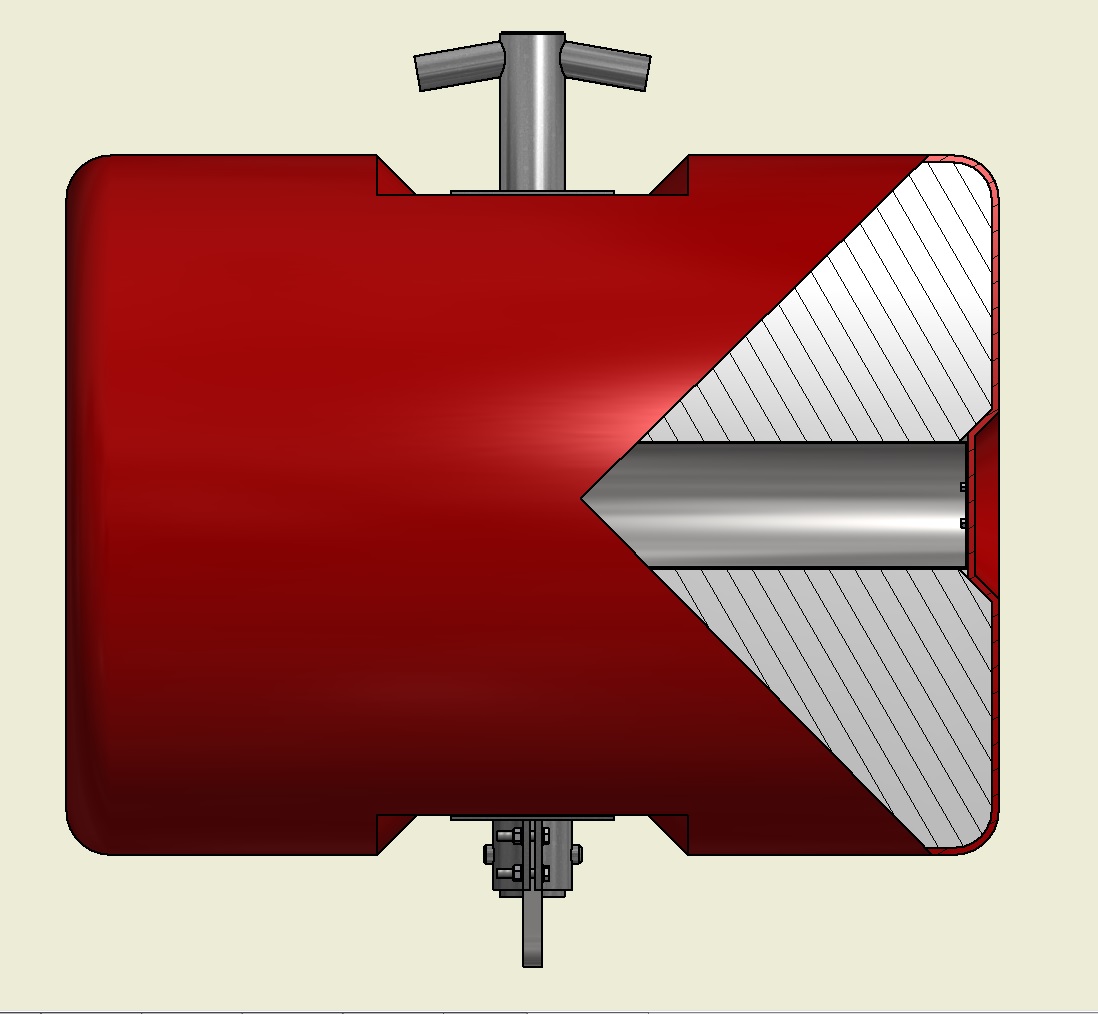

Ocean 3 Foam Filled Chain Support Buoys with chain passing through the Buoy, from 2,5 Tons to 10 Tons (or more) - Cylindrical or rectangular in shape - Fitted with chain locking plate or chain locking pin, on one of both ends.

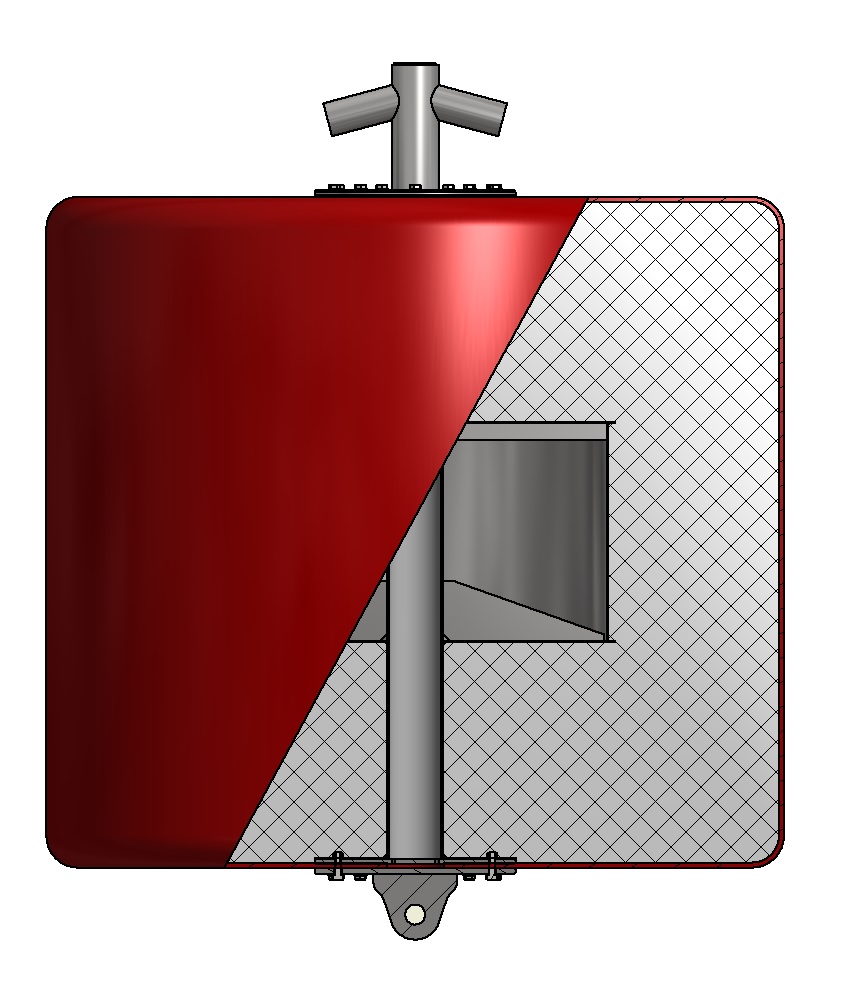

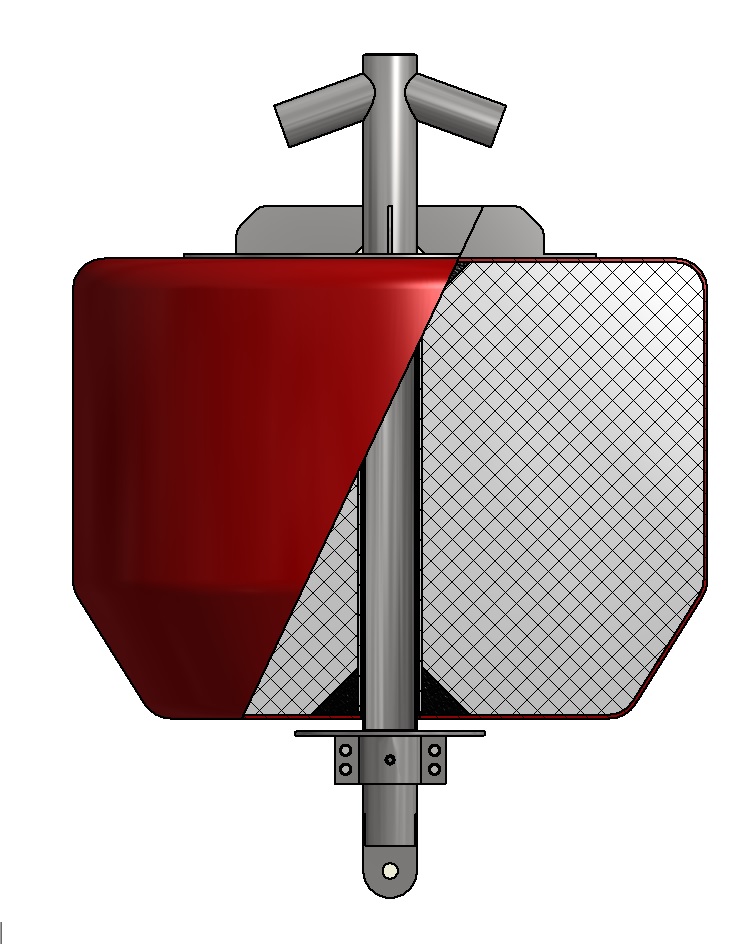

D) FOAM FILLED ANCHOR BUOYS

Ocean 3 Foam Filled Anchor Buoys from 0,5 Ton to 10 Tons (or more) - Cylindrical or rectangular in shape -Steel through axle fitted with an inner casing, inside the buoy - Typically fitted with a mooring Te on top (crucifix), or mooring flange. On lower part : Mooring pad eye for the anchor line. Those anchor Buoys are for the mooring of light weight vessels or for temporary moorings. For heavy vessel mooring, please see "Mooring Buoys".

E) FOAM FILLED ANCHOR BUOY - REMOVABLE AXLE

Ocean 3 Foam Filled Anchor Buoys from 0,5 Ton to 10 Tons (or more) - Cylindrical or rectangular in shape -Steel through axle fitted with an inner casing, inside the buoy – Typically fitted with a mooring Te on top (crucifix), or mooring flange. On lower part: Mooring pad eye for the anchor line. Those anchor buoys will have removable steel work, for repairs or removal, to facilitate maintenance; fixed with a clamp on the bottom, a larger plate on the top to take the forces and smaller plate on the bottom.

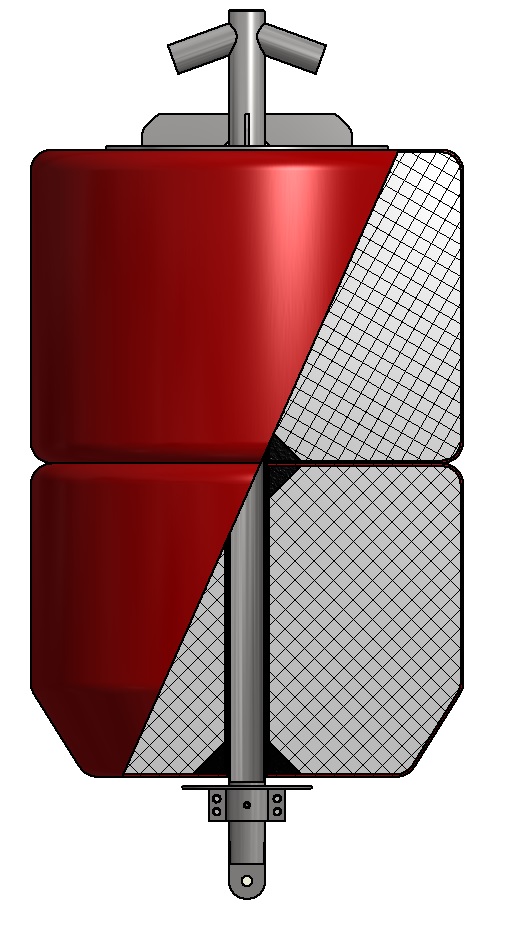

F) FOAM FILLED MODULAR ANCHOR BUOY

Chain buoyancy units ranging from 2,5 Ton to 10 Tons (or more) - Cylindrical or rectangular in shape –removable steelwork – Typically fitted with a mooring Te on top (crucifix), or mooring eye. On lower part: Mooring pad eye for the anchor line. Those anchor Buoys will have removable steel work, for repairs or removal, to facilitate maintenance; fixed with a clamp on the bottom, a larger plate on the top to take the forces and smaller plate on the bottom. Modular floats to add or reduce the amount of buoyancy for the buoys.

G) FOAM FILLED PICK-UP BUOYS

Small Buoyancy units from 50kg to 1t to support a small length of rope or cable wire so to pick up the line. Cylindrical or spherical in shape. Fitted with swivels on each ends.

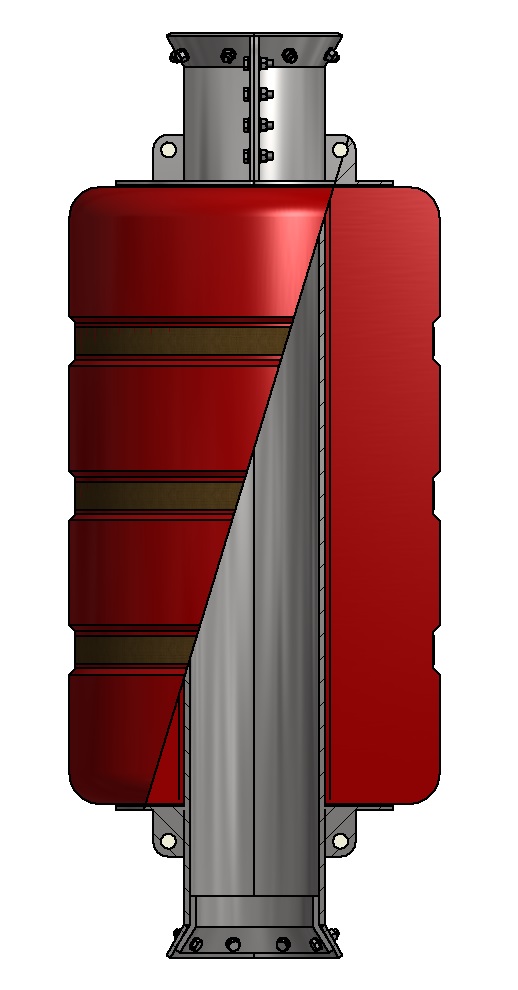

H) FOAM FILLED MODULAR CHAIN THROUGH BUOYS

Ocean 3 Foam Filled Chain buoyancy units ranging from 2,5 Ton to 10 Tons (or more), specifically made for FSO or FPSO and the oil & gas industry - Cylindrical or rectangular in shape. Through steel work with locking plate on one or both ends. Made in 2 x half modular sections to facilitate the installation and maintained with straps, without needing to move the mooring line.

I) FOAM FILLED BARREL BUOYS

Ocean 3 Foam Filled Barrel Buoyancy units ranging from 0,5 Ton to 10 Tons (or more), cylindrical shape. The inner steelwork will be in a cross formation, through the diameter, allowing the buoy to swivel; as opposed to having a more traditional steelwork through the length of the buoy.

II - DESIGN OF FOAM FILLED BUOYS AND FLOATS

Our Technical Department remains at your disposal to help with :

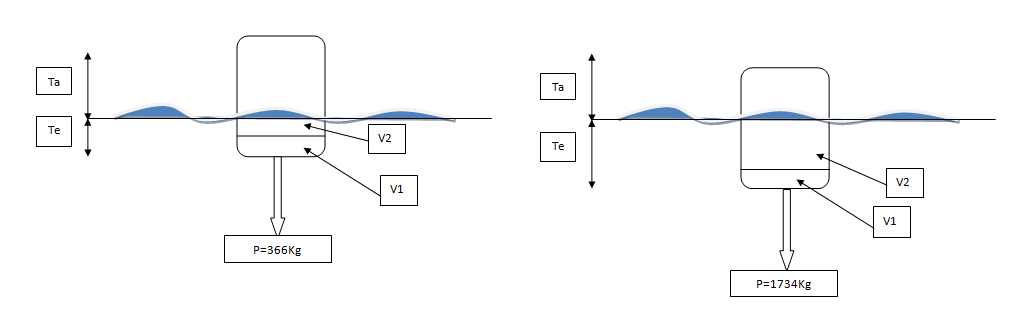

- The design of a float with sufficient buoyancy seeking the best compromise between "volume / cost" of the Buoy

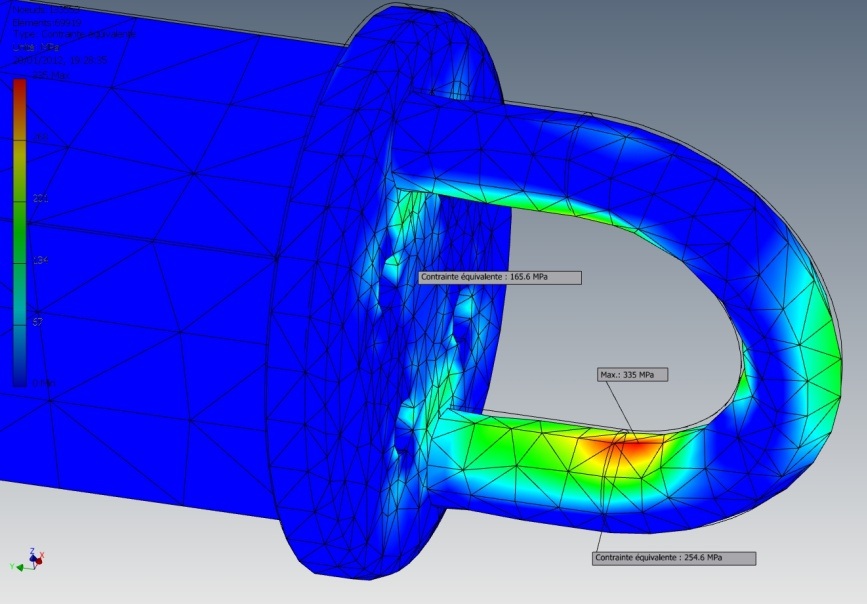

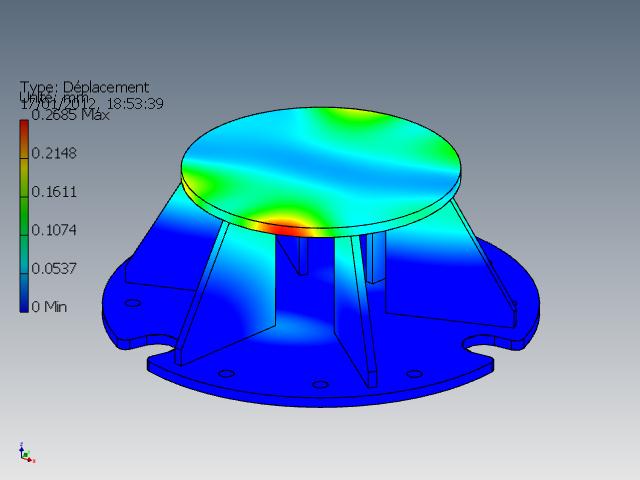

- The design of the internal metal frame and accessories (if any) to distribute and take the strengths/forces through the structure.

- Stability calculations or sea behavior during operation

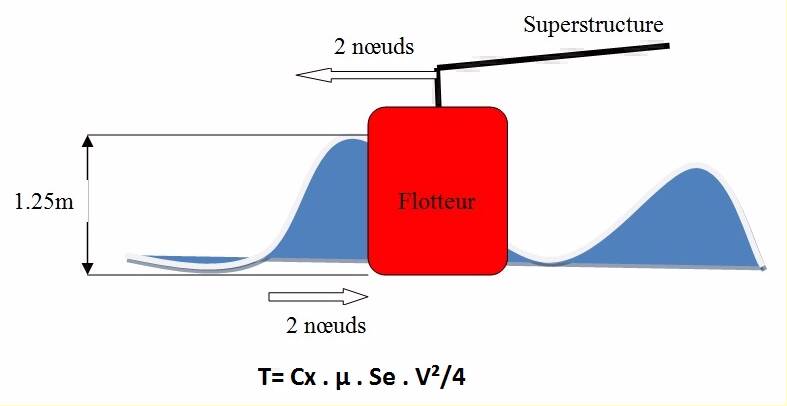

- Evaluation of the drag on the considered Float

Ocean 3 Foam Filled Buoys & floats types

Many kinds of Foam Filled Buoys & Floats exist in our range, as follows :

- Anchor Pendant Buoys

- Utility Floats

- "Pick-up" Buoys

- Chain support Buoys

- Floats for Umbilicals

- Modular Buoys

- Marker, Navigation Buoys

Accessories

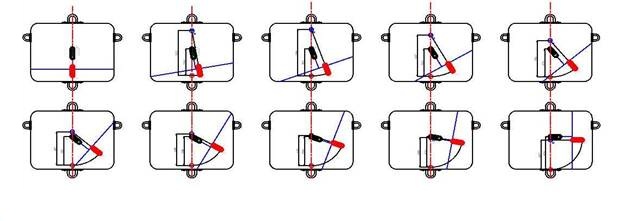

Many different types of end fittings are available as shown below for our Ocean 3 Buoys & Floats. All fittings are a welded steel construction, are all hot-dip galvanised or painted with inorganic zinc/epoxy paint for corrosion protection.

According to use, they can be : Clevis or swivel Eye, Through tube with Chain locking Plate or Pin, Pick-up Tees (crucifix), Clamp Systems, or whichever are required...

TO HAVE AN OVERVIEW ON ALL OUR RANGES :